Air dry clay is a versatile crafting material that hardens and cures without the need for a kiln or oven. It’s widely used for creating sculptures, home décor, jewelry, and even functional items like planters. However, one challenge that arises when working with air dry clay, especially for outdoor or functional projects, is ensuring its durability and water resistance. Without proper waterproofing, air dry clay is prone to absorbing moisture, which can lead to cracking, fading, or deterioration over time, particularly when exposed to the elements. For items intended for outdoor use or those requiring some form of water exposure, waterproofing becomes essential to maintain the longevity and structural integrity of the clay creations.

To make air dry clay waterproof, it is crucial to apply specific techniques or products designed to seal and protect the surface from water damage. Several methods can help in achieving this, such as using clear acrylic sealants, waterproof varnishes, or specialized clay sealers. These products form a protective layer on the surface of the clay, preventing moisture from seeping in. Additionally, some crafters choose to coat their clay with oil-based finishes, which further enhance its water-resistant properties. It’s also important to ensure that the clay is thoroughly dry and cured before applying any sealant to achieve the best results.

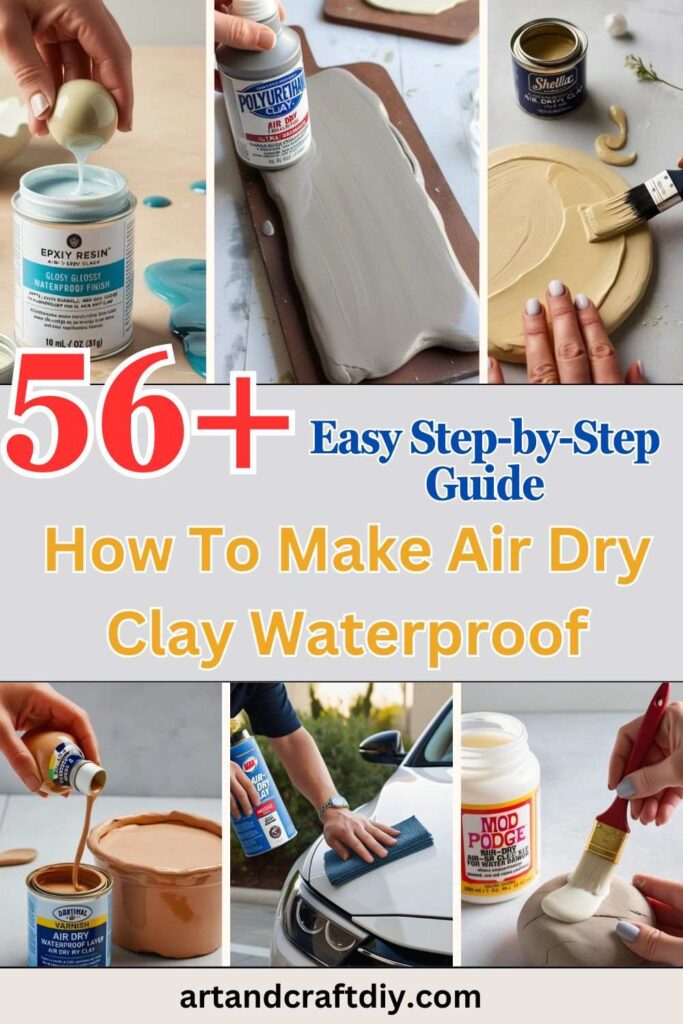

How To Make Air Dry Clay Waterproof

Air Dry Clay Waterproof refers to a type of air-dry clay that has been specifically formulated to be waterproof once it dries. This type of clay is ideal for outdoor projects, sculptures, or items that will be exposed to moisture or weather conditions. It’s a versatile material, typically used for creating crafts, home decor, and art pieces, as it doesn’t require baking to harden. Once fully cured, it resists water and maintains its durability and shape, making it suitable for both indoor and outdoor use.

Use Clear Acrylic Sealer for Waterproofing

To protect your air-dry clay project from water damage, using a clear acrylic sealer is one of the easiest and most effective methods. It will form a protective coat that shields the surface without affecting the look of your clay.

Materials Used:

- Clear acrylic sealer (spray or liquid)

- Paintbrush (if using liquid sealer)

Steps:

- Ensure the air-dry clay is completely dry before applying the sealer.

- If using spray, hold the can about 6–8 inches from the surface and spray in even strokes.

- For liquid sealer, dip a clean paintbrush into the sealer and apply a thin, even coat over the clay.

- Allow the first coat to dry completely, then apply a second coat for extra protection.

Apply Mod Podge for a Water-Resistant Base Layer

Mod Podge is a versatile adhesive and sealer available in matte, gloss, and satin finishes. While it’s not fully waterproof, it creates a strong water-resistant base coat that helps protect air-dry clay from light moisture and dust.

Important: For a truly waterproof seal, you’ll need to apply a clear waterproof topcoat—like acrylic spray sealant, polyurethane, or marine varnish—over the dried Mod Podge.

Materials Used:

- Mod Podge (Gloss or Matte)

- Paintbrush

Steps:

- Let your air-dry clay project dry fully before beginning.

- Using a paintbrush, apply a thin layer of Mod Podge to the surface of your project.

- Wait for the first coat to dry, then apply additional coats for a stronger seal.

- Let the final coat dry completely to ensure the clay is waterproof.

Use Silicone Sealant for Strong Waterproofing

Silicone sealant is a heavy-duty option for waterproofing your air-dry clay creations. It provides an extra layer of protection against water and moisture.

Materials Used:

- Clear silicone sealant

- Paintbrush or applicator

Steps:

- Allow the clay to fully dry before applying the silicone.

- Squeeze the silicone sealant onto a clean surface or use an applicator.

- Apply a thin, even layer of silicone over the clay surface, ensuring all areas are covered.

- Allow the silicone to cure for 24 hours before using or handling.

Use Beeswax to Seal Clay

Beeswax provides a natural, water-resistant coating for air-dry clay. It’s a good choice if you prefer a non-toxic, eco-friendly waterproofing solution.

Materials Used:

- Beeswax

- Hairdryer (optional)

- Soft cloth

Steps:

- Rub a thin layer of beeswax onto the surface of your clay.

- For a smooth finish, you can heat the beeswax with a hairdryer to make it easier to apply.

- Buff the surface with a soft cloth to remove any excess wax and create a polished finish.

- Let the clay sit for a few hours to allow the wax to set.

Use Varnish for a Hard Waterproof Layer

Varnish creates a hard, protective shell that is highly water-resistant. This method works well for decorative pieces exposed to the elements.

Materials Used:

- Varnish (Gloss or Satin)

- Paintbrush

Steps:

- Once your air-dry clay is completely dry, use a paintbrush to apply varnish in thin layers.

- Allow each layer to dry before applying the next.

- You may apply up to three coats for added durability.

- Let the project cure for 24 hours to ensure the varnish is fully hardened.

Waterproof with Paraffin Wax

Paraffin wax is another natural option that offers a smooth, waterproof finish for your air-dry clay creations. It’s great for smaller items or crafts that need water resistance.

Materials Used:

- Paraffin wax

- Double boiler or microwave-safe container

- Cloth or sponge

Steps:

- Melt the paraffin wax using a double boiler or microwave.

- Dip your dry clay object into the melted wax or apply it with a sponge.

- Let the wax set for 30 minutes to an hour, then apply another coat if needed.

- Allow the project to cool completely before handling.

Use Polyurethane for an Ultra-Strong Waterproof Layer

Polyurethane is a long-lasting, durable finish that protects air-dry clay from water and wear. It’s ideal for items like outdoor sculptures or kitchenware.

Materials Used:

- Polyurethane (water-based or oil-based)

- Foam brush

Steps:

- Use a foam brush to apply an even layer of polyurethane to the surface of the clay.

- Allow the first coat to dry, then apply additional coats as needed.

- Lightly sand between coats for a smoother finish.

- Let the final coat cure for at least 24 hours before exposing the clay to water.

Apply Car Wax for Extra Protection

Car wax is designed to repel water and protect against moisture, making it an effective option for waterproofing air-dry clay.

Materials Used:

- Car wax

- Soft cloth

Steps:

- Apply a thin layer of car wax to the surface of the dried clay with a soft cloth.

- Buff the wax into the surface, working it into the clay.

- Let the wax dry for a few minutes, then buff the excess off with a clean cloth.

- Reapply for additional layers of protection if needed.

Use Epoxy Resin for a Glossy Waterproof Finish

Epoxy resin creates a high-gloss, durable, and waterproof finish. It’s ideal for projects that require both a shiny look and excellent water resistance.

Materials Used:

- Epoxy resin (2-part system)

- Plastic cup for mixing

- Stir stick

- Gloves

Steps:

- Mix the epoxy resin and hardener according to the package instructions.

- Using a stir stick, apply the mixed resin to the surface of your clay.

- Work quickly, as epoxy can start setting fast.

- Allow the resin to cure for 24–48 hours before touching or using your project.

Use Shellac to Seal and Waterproof

Shellac is a versatile sealer that adds a glossy finish to your air-dry clay, providing a protective barrier against moisture.

Materials Used:

- Shellac

- Paintbrush

Steps:

- After your clay piece is dry, apply a thin coat of shellac with a paintbrush.

- Wait for the first coat to dry before applying additional layers.

- You may apply 2–3 coats for a strong seal.

- Let the project sit for at least 24 hours before exposing it to moisture.

Waterproof with PVA Glue

PVA glue is an affordable and simple option to waterproof your air-dry clay. It works by forming a flexible, clear barrier when applied.

Materials Used:

- PVA glue (white glue)

- Paintbrush

Steps:

- Ensure your clay project is completely dry.

- Using a paintbrush, apply a layer of PVA glue over the surface.

- Let it dry and apply a second or third layer for increased waterproofing.

- Allow the project to dry for at least 24 hours before use.

Use Waterproof Paint

Waterproof paint offers a long-lasting finish that protects your air-dry clay from moisture. It’s ideal for both decorative and functional items.

Materials Used:

- Waterproof paint (acrylic or enamel)

- Paintbrush

Steps:

- Choose a waterproof paint suitable for your project.

- Apply the paint evenly over the surface of the clay with a paintbrush.

- Allow the first layer to dry completely before applying additional coats.

- Let the paint cure for 24 hours for the best protection.

Apply Linseed Oil for Natural Waterproofing

Linseed oil is an eco-friendly option that penetrates the clay to create a water-resistant finish. It’s ideal for natural and rustic looks.

Materials Used:

- Boiled linseed oil

- Cloth

Steps:

- Pour a small amount of linseed oil onto a cloth.

- Rub the oil into the surface of the air-dry clay.

- Let the oil absorb into the clay for a few hours.

- Buff off any excess oil with a clean cloth for a smooth finish.

Use Waterproof Modelling Paste for a Thick Coat

Modelling paste can be applied to create a thick, water-resistant layer on top of your air-dry clay pieces. This method is useful for larger or sculptural items.

Materials Used:

- Waterproof modelling paste

- Palette knife or spatula

Steps:

- Apply a thin layer of modelling paste onto the surface of the clay using a palette knife.

- Smooth out the paste to ensure an even coating.

- Let the paste dry completely before adding another layer for increased durability.

- Allow your piece to cure for 24 hours before exposure to moisture.

Use Hydrophobic Spray for Quick and Easy Waterproofing

Hydrophobic sprays are a fast and efficient way to protect your air-dry clay from water damage, especially for small crafts or items not regularly exposed to water.

Materials Used:

- Hydrophobic spray

- Gloves (optional)

Steps:

- Hold the spray can 6–8 inches from the surface of the dry clay.

- Spray the hydrophobic solution in a light, even coat.

- Allow the coating to dry for 24 hours for the best protection.

- Reapply as necessary, depending on the frequency of exposure to water.

Coat Clay with Liquid Latex for Waterproofing

Liquid latex is a flexible, rubbery coating that provides a waterproof barrier for air-dry clay. It’s perfect for items that require flexibility in addition to water resistance.

Materials Used:

- Liquid latex

- Paintbrush

Steps:

- Apply a thin layer of liquid latex to the dry clay surface using a paintbrush.

- Let it dry and repeat the process for additional layers.

- Once fully dry, the latex will form a flexible, waterproof barrier.

- Let the project cure for 24 hours before use.

Use Polycrylic for a Clear Waterproof Finish

Polycrylic is a clear, water-based coating that creates a durable, waterproof barrier while maintaining the natural look of your air-dry clay.

Materials Used:

- Polycrylic (water-based)

- Paintbrush

Steps:

- Apply the polycrylic with a soft-bristled brush.

- Allow the first coat to dry before applying additional coats for added protection.

- Sand lightly between layers for a smoother finish.

- Let the project dry for at least 24 hours to ensure maximum protection.

Use Gesso for Waterproofing and Texturing

Gesso is commonly used as a primer for painting, but it can also provide a waterproof finish for your air-dry clay while adding texture.

Materials Used:

- Gesso (white or clear)

- Paintbrush

Steps:

- Apply a thin layer of gesso to the surface of your clay.

- Allow it to dry and apply additional layers for increased durability.

- Sand between layers for a smoother finish, if desired.

- Once fully dry, your clay will have a waterproof finish and enhanced texture.

Use Water-Repellent Fabric Protector Spray

A water-repellent fabric protector spray can also work on air-dry clay to offer a quick waterproofing solution.

Materials Used:

- Fabric protector spray

- Gloves (optional)

Steps:

- Spray the fabric protector on the surface of the dry clay, holding the can about 6 inches away.

- Allow the first coat to dry before applying a second coat for added protection.

- Let your project dry for 24 hours before using it in wet conditions.

Apply Shellac Varnish for a Smooth, Glossy Waterproof Finish

Shellac varnish creates a glossy finish while providing strong waterproof protection. It’s a great choice for decorative clay pieces exposed to moisture.

Materials Used:

- Shellac varnish

- Paintbrush

Steps:

- Apply shellac varnish to the surface of the dry clay using a paintbrush.

- Let the first coat dry before applying additional layers for maximum waterproofing.

- Once the varnish has dried fully, your project will be water-resistant and glossy.

Use Water-Based Silicone Coating for a Flexible Waterproof Layer

A water-based silicone coating provides a flexible and waterproof finish for air-dry clay, especially if you plan to use your pieces outdoors.

Materials Used:

- Water-based silicone coating

- Paintbrush

Steps:

- Apply a thin layer of silicone coating over the dry air-dry clay.

- Allow the first layer to dry completely before adding another.

- Use a third layer if needed to ensure maximum protection from water.

- Let the silicone cure for 24 hours before handling.

Use Chalk Paint for Waterproofing and Decorative Effect

Chalk paint can provide a stylish, matte waterproof finish for your air-dry clay while also allowing you to achieve a vintage or rustic look.

Materials Used:

- Chalk paint

- Paintbrush

Steps:

- Apply a thin coat of chalk paint to your dry air-dry clay project.

- Let it dry completely before applying additional coats.

- Use a wax finish for extra durability if needed.

Waterproof with Coconut Oil for a Natural Finish

Coconut oil offers a natural and moisturizing way to waterproof your air-dry clay, particularly if you want a subtle, matte finish.

Materials Used:

- Coconut oil

- Soft cloth

Steps:

- Apply a small amount of coconut oil onto a soft cloth.

- Rub the oil gently into the surface of the clay.

- Buff away any excess with a clean, dry cloth.

Apply Aqueous Finish for Clay-Based Projects

An aqueous finish provides an extra layer of protection for your clay creations. It’s perfect for both decorative and functional items.

Materials Used:

- Aqueous finish

- Paintbrush

Steps:

- Apply an even layer of aqueous finish to your clay piece using a paintbrush.

- Allow the first layer to dry before applying a second for enhanced protection.

Use Liquid Rubber for Flexible Waterproofing

Liquid rubber is a versatile and flexible solution for waterproofing air-dry clay. It’s ideal for creating pliable, water-resistant projects.

Materials Used:

- Liquid rubber

- Applicator brush

Steps:

- Apply the liquid rubber in thin, even layers using an applicator brush.

- Let each layer dry before applying another to ensure the best waterproofing.

- Allow the project to cure for 24 hours before exposure to moisture.

Waterproof with Oil-Based Paint

Oil-based paint not only provides a rich finish but also creates a durable and water-resistant surface for your air-dry clay.

Materials Used:

- Oil-based paint

- Paintbrush

Steps:

- Apply a thin coat of oil-based paint over your air-dry clay.

- Let the first coat dry before adding additional layers if necessary.

- Allow the paint to cure for a full 48 hours before exposing the clay to moisture.

Use Glycerin for a Soft, Waterproof Finish

Glycerin is a great choice for creating a soft, flexible waterproof layer on your air-dry clay, making it a good option for delicate items.

Materials Used:

- Glycerin

- Soft cloth

Steps:

- Apply a small amount of glycerin to a soft cloth.

- Rub the glycerin gently into the surface of the clay.

- Allow it to absorb and create a flexible, waterproof barrier.

Use Concrete Sealer for Large Clay Sculptures

Concrete sealer is an excellent option for large clay sculptures that will be exposed to the elements. It provides long-lasting waterproofing.

Materials Used:

- Concrete sealer

- Paintbrush

Steps:

- Apply the concrete sealer with a paintbrush to your dried clay sculpture.

- Allow the first coat to dry completely before applying additional layers.

- Let the sculpture cure for 24–48 hours before exposure to water.

Apply Silicone Rubber Coating for Industrial Waterproofing

For industrial or heavy-duty waterproofing, silicone rubber coating works wonders. It creates a durable, flexible barrier against moisture.

Materials Used:

- Silicone rubber coating

- Applicator brush

Steps:

- Apply the silicone rubber coating to your clay surface in thin layers.

- Let each layer dry before adding another for enhanced protection.

- Cure the piece for 24–48 hours before exposing it to moisture.

Use Waterproof Coating for Outdoor Clay Planters

To protect outdoor clay planters, use a waterproof coating designed specifically for outdoor use. This will prevent water from damaging the clay over time.

Materials Used:

- Waterproof outdoor coating

- Paintbrush

Steps:

- Apply an even layer of waterproof coating to your clay planter.

- Allow it to dry and apply a second coat for maximum water resistance.

- Allow the coating to cure for 24–48 hours before using it outdoors.

Common Mistakes to Avoid When Sealing Projects

Sealing is a crucial step in many DIY and craft projects, whether you’re working with clay, wood, or other materials. However, it’s easy to make mistakes that can affect the final result. Here are some common sealing mistakes to watch out for:

- Applying Sealer Before the Clay Is Fully Dry

One of the most common mistakes is applying a sealer too soon. If your clay isn’t completely dry, it can trap moisture underneath the sealant, which may lead to cracking or an uneven finish. - Using the Wrong Type of Sealer for the Project

Not all sealers are created equal. Choosing the wrong sealer for your project (e.g., using a glossy finish when you want a matte effect or using a wood sealer on clay) can lead to poor results or even damage the material you’re working with. - Over-Sealing or Under-Sealing

Both over-sealing and under-sealing can ruin your work. Over-sealing can cause a heavy, sticky, or uneven surface, while under-sealing may leave your project unprotected and vulnerable to damage. Achieving the right balance is key to a successful result.

By being mindful of these mistakes, you can ensure your sealing process goes smoothly and your projects turn out as intended.

Additional Tips for Best Results in Clay Project Care

Creating and maintaining a beautiful clay item requires not just skill in the shaping and molding, but also proper sealing and care. Here are some essential tips to ensure your clay projects remain durable and beautiful over time, especially when exposed to different environments.

- Sealing the Bottom and Edges of Your Clay Item

- Always seal the bottom and edges of your clay item to prevent moisture from seeping in. These areas are prone to absorbing water, which can weaken the structure over time.

- Apply a thin, even coat of sealer using a brush or sponge, making sure to cover all exposed surfaces. Be gentle to avoid disturbing the texture or design of the clay.

- Protecting Your Clay Project from Potential Damage in High-Moisture Environments

- In areas with high humidity, such as kitchens or bathrooms, clay items can absorb moisture, leading to cracking or degradation. Consider using a high-quality sealer specifically designed for waterproofing.

- Keep your clay projects away from direct water exposure, such as sinks or bathtubs, and avoid placing them in damp spaces where condensation can form.

- Maintenance and Reapplication of the Sealer Over Time

- Over time, the sealer may wear down, especially with frequent handling or exposure to moisture. Inspect your clay items periodically to ensure the sealer is intact.

- Reapply the sealer as necessary, particularly to areas that show signs of wear or discoloration. Light sanding before reapplication can help the new layer adhere more effectively.

By following these tips, you can enhance the longevity and beauty of your clay creations, ensuring they remain in excellent condition for years to come.

FAQ

What is air dry clay?

Air dry clay is a type of clay that hardens when left exposed to air. Unlike traditional clay, it doesn’t require baking in a kiln or oven. It’s often used for crafting, sculptures, and other DIY projects.

Can air dry clay be waterproofed?

Yes, air dry clay can be made waterproof. While it’s naturally porous, applying a proper sealant can make it resistant to water and moisture.

What materials do I need to waterproof air dry clay?

To waterproof air dry clay, you’ll need a waterproofing sealant such as polyurethane, acrylic sealer, or a clear varnish. You’ll also need a paintbrush or spray bottle to apply the sealer.

How do I apply a waterproof sealant to air dry clay?

After your air dry clay project is fully dry, apply the sealant using a paintbrush or spray. Ensure you cover the entire surface evenly. Let it dry completely between coats, usually 2-3 coats for full waterproofing.

Hi, I’m Victoria, an art and craft teacher at Newark City Schools, where I have the joy of working with middle school students to help them explore their creativity and develop their artistic talents. I believe that art is a powerful way for students to express themselves, and I strive to make every lesson a fun, engaging, and inspiring experience.

I created this website to share the art and craft projects, techniques, and resources that I use in my classroom, hoping to inspire both educators and young artists alike. Whether you’re a teacher looking for new ideas or a student eager to try something new, I’m excited to provide creative tools and projects that anyone can enjoy.

When I’m not in the classroom, I love experimenting with different art forms and learning new crafting techniques. My goal is to help others discover the joy of making things with their hands, and I hope my website serves as a space for everyone to explore their creative potential.